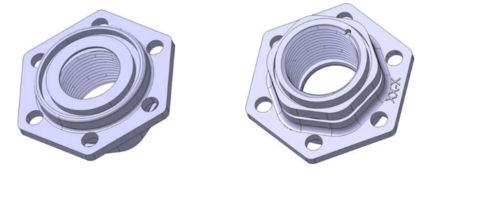

Valve Boss/ Metal Insert

2 USD ($)/Number

Product Details:

- Pressure Rated for up to 250 bar

- Capacity N/A (insert; determined by application)

- Wall Thickness 2mm to 4mm nominal

- Temperature -20C to 200C

- Material Mild Steel, Stainless Steel, Brass

- Structure Solid machined metal insert with boss

- Power Manual/Not applicable

- Click to View more

X

Valve Boss/ Metal Insert Price And Quantity

- 1000 Number

- 2.00 - 4.00 USD ($)/Number

- 2 USD ($)/Number

Valve Boss/ Metal Insert Product Specifications

- -20C to 200C

- 2mm to 4mm nominal

- Approx. 40-120 grams depending on size

- Varies 8-24mm

- Mild Steel, Stainless Steel, Brass

- Manual/Not applicable

- Solid machined metal insert with boss

- N/A (insert; determined by application)

- Standard transition rod for valve fitment

- Depends on application; O-ring or oil seal compatible

- Rated for up to 250 bar

- Diameter: 20-50mm; Height: 20-40mm

Product Description

Jump on the opportunity to experience the finest Valve Boss/Metal Insert, crafted with astounding precision. Designed for exceptional performance, each insert features a precision-turned surface, zinc plated or chrome coated for lasting durability. Customize your order with a range of metric or imperial threads and anti-corrosive materials for superior corrosion resistance. Pick yours today-instant checkout available. Ideal for hydraulic and pneumatic valve assemblies, these inserts offer 0.02mm tolerance, up to 60 HRC hardness, and flexibility in installation. Choose from tailored sizes, bulk or individual packaging, and enjoy impressive strength capable of withstanding up to 250 bar pressure. Manufactured and exported directly from India by an industry-leading producer.

Applications and Special Features of Valve Boss/Metal Insert

Widely used by OEMs, engineering firms, valve manufacturers, and maintenance professionals, our Valve Boss/Metal Insert stands out for its robust structure and exceptional tolerance precision. Designed to fit seamlessly into hydraulic and pneumatic systems, it boasts features like corrosion resistance, custom thread types, and high hardness up to 60 HRC. Produced using state-of-the-art CNC machines, this metal insert ensures reliable press-fit or threaded installation, making every machine assembly efficient and dependable.

Sample Policy, Certifications, and Supply Capability

Express shipping is available for samples, which can be requested at nominal outlay reflective of the insert's market value. Our certifications include stringent quality assurance and material testing standards. We proudly serve global markets, maintaining high supply ability to meet both bulk and custom orders year-round. Each shipment is carefully packaged-bulk or individual-as specified, ensuring you receive your product in impeccable condition, ready for immediate installation or integration into your assembly line.

Applications and Special Features of Valve Boss/Metal Insert

Widely used by OEMs, engineering firms, valve manufacturers, and maintenance professionals, our Valve Boss/Metal Insert stands out for its robust structure and exceptional tolerance precision. Designed to fit seamlessly into hydraulic and pneumatic systems, it boasts features like corrosion resistance, custom thread types, and high hardness up to 60 HRC. Produced using state-of-the-art CNC machines, this metal insert ensures reliable press-fit or threaded installation, making every machine assembly efficient and dependable.

Sample Policy, Certifications, and Supply Capability

Express shipping is available for samples, which can be requested at nominal outlay reflective of the insert's market value. Our certifications include stringent quality assurance and material testing standards. We proudly serve global markets, maintaining high supply ability to meet both bulk and custom orders year-round. Each shipment is carefully packaged-bulk or individual-as specified, ensuring you receive your product in impeccable condition, ready for immediate installation or integration into your assembly line.

FAQ's of Valve Boss/ Metal Insert:

Q: How can I order a customized Valve Boss/Metal Insert?

A: To order a customized Valve Boss/Metal Insert, specify your required dimensions, material, and thread type. Our team will provide a tailored solution based on your application and deliver prompt assistance during the entire process.Q: What are the main benefits of using your precision-turned metal inserts in valve assemblies?

A: Our precision-turned metal inserts offer exceptional tolerance, corrosion resistance, and high hardness, enhancing the durability and reliability of valve assemblies under demanding conditions.Q: Where can your Valve Boss/Metal Inserts be used?

A: These inserts are suitable for hydraulic and pneumatic systems, industrial valve assemblies, and are compatible with various machine equipment across manufacturing sectors.Q: What is the process for ensuring corrosion resistance on the inserts?

A: Corrosion resistance is achieved by using special anti-corrosive materials or surface coatings like zinc plating or chrome coating, determined by your application requirements.Q: When should I consider press-fit versus threaded installation options?

A: Press-fit installation is ideal for rapid assembly and secure placement without threads, while threaded versions allow for easy removal or adjustment. Choose based on your application's maintenance and assembly requirements.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Mobile No:- +91 9466660069

Mobile No:- +91 9466660069 Send Inquiry

Send Inquiry Send SMS

Send SMS